1400℃ Single Zone Horizontal Tube Furnace

Model No.: STG-40-14

Heating Zone: 300mm

Continuous Temp.: 1300℃

Heating Element: High Quality SIC Rod

Temperature Precision: ±1℃

Thermocouple: S Type

| Model | STG-40-14 | STG-60-14 | STG-80-14 | STG-100-14 | STG-110-14 | STG-120-14 | Customized |

| Chamber Size(WxLxH)mm | Φ40 | Φ60 | Φ80 | Φ100 | Φ110 | Φ120 | Any size |

| Heating Zone Length(mm) | 300 | 300 | 300 | 300 | 300 | 300 | Any size |

| Type | Benchtop | ||||||

| Furnace Structure | Chamber Material,Temperature Controller System, Heating Element, Furnace Shell and Other assistant parts | ||||||

| Max Temperature | 1400℃ | ||||||

| Continue Operating Temp. | 1300℃ | ||||||

| Power Supply | 220V/2KW | 220V/3KW | 220V/4KW | 220V/5KW | 220V/5KW | 220V/6KW | Depends on size |

| Heating Element | High Quality SIC Rod | ||||||

| Chamber Material | High temperature polycrystal alumina ceramic fiber material | ||||||

| Temperature Precision | ±1℃ | ||||||

| Thermocouple | S type | ||||||

| Temperature Controller | SHIMADEN (Japan) brand intelligent microcomputer PID controller can program 4 groups 32 segments | ||||||

| Electronic Component | SCHNEIDER(France)electronics brand | ||||||

| Heating Rate | ≤ 15℃/min ( suggest 15℃/min for longer life using of furnace ) | ||||||

| Safety Protection | Overheat and Thermocouple-break alarm | ||||||

| Certification | ISO9001 CESGS | ||||||

| Furnace Shell | High quality cold-rolled steel sheets CNC processing | ||||||

| Insulation | High quality thermal insulation material to ensure a good uniformity | ||||||

| Accessories |

One pair of high temperature furnace gloves One piece offurnace hook One set of sealing flanges with quartz tube |

||||||

| Optional |

Paperless recorder Quartz boat Vacuum pump |

||||||

1400℃ STG Series products are mainly applied for the heat treatment of samples under vacuum or protective atmosphere, high-quality silicon carbide rod is used for heating element, and the temperature controller uses microcomputer PID control module to achieve precise temperature control and constant temperature requirements. The product uses the new-type ceramic fiber material as the furnace chamber material; the furnace tube material is fine, and the tube is sealed by stainless steel flanges on its both ends, the furnace can be work under the vacuum, there are air inlet and air outlet on the flange, also it can be filled in protective air, the precision needle-valve may adjust the air inlet flow rate.

1400°C tube furnace mainly provides high temperature heat treatment environment for industrial, research institutes, factories and other industrial laboratories, and is applied to new materials such as metal materials, ceramic materials, nano materials, and semiconductor materials.

1700-U Type Heating Elements

Material Grade: 1700 Diameter: D1/D2, mm/mm Hot zone lengt...

GD Type Heating Elements

Model Type: GD Outer diameter: OD,mm Hot zone length: HZ,m...

1700-W Type Heating Elements

Material Grade: 1700 Diameter: D1/D2, mm/mm Hot zone lengt...

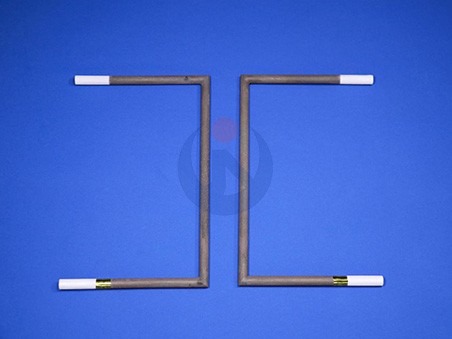

H Type Heating Elements

Model type: H Outer diameter: OD, mm Hot end length: HZ, m...

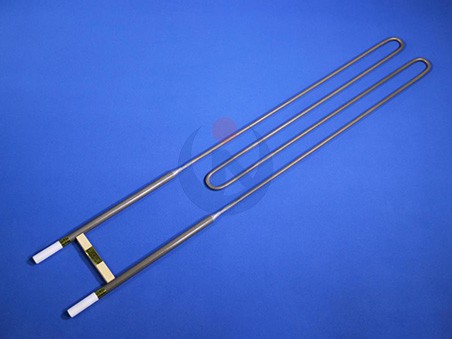

W Type Heating Elements

Model Type: W Outer diameter :OD,mm Hot zone length: HZ,mm

DM Type Heating Elements

Model type: DM Outer diameter: OD, mm Hot end length: HZ, ...