Silicon molybdenum rods are somewhat soft at high temperatures (above 1500 degrees), but hard and brittle at low temperatures. In order to avoid stress during temperature changes and facilitate thermal expansion and contraction of components, it is best to use a free vertical hanging installation method. The disassembly and replacement of the hoisting components is also more convenient, without waiting for the furnace to cool down.

The following items must be paid attention to when installing silicon molybdenum rods:

1. Corundum bricks are used as the lining material, and the mass fraction of Fe2O3 should be less than 1%, because it interacts with the protective film to form fusible silicate, which accelerates the destruction of the heating elements.

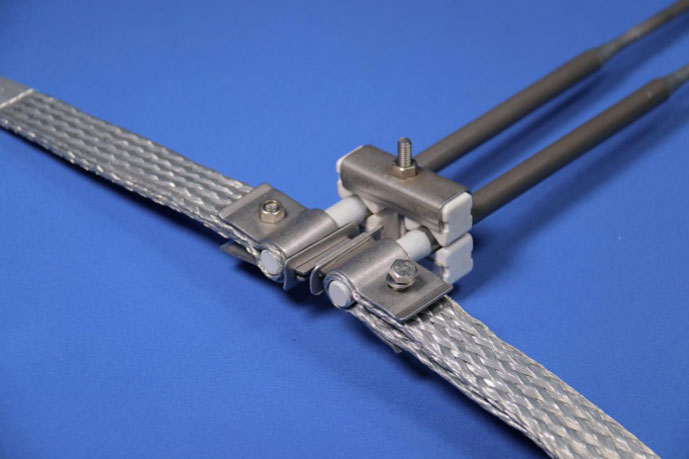

2. The hot furnace gas leaking from the cold end will not only increase the heat loss of the furnace, but will even burn out the conductive tape chuck and lead clip. Therefore, it is best to use asbestos chuck.

3. Because the silicon molybdenum rod is a brittle material, it has low bending strength and cannot withstand impact. Protective measures should be taken during installation to prevent it from breaking. When connecting the conductive tape, the asbestos chuck (or porcelain chuck) must be installed first, and the clamping force shall not be excessive.

4. Install the silicon molybdenum rods into the plug bricks. In order to avoid the mechanical stress caused by the loading and unloading movement, the plug bricks should be made of separate bricks made of foam corundum bricks.

5. Insert the plug brick with silicon molybdenum rods into the prepared space on the furnace roof. The plug bricks should protrude from the furnace roof to facilitate disassembly.

6. Connect the conductive tape with the connection bracket that has been prepared, but avoid the tension of the conductive tape and unnatural twisting mechanical stress.

7. In order to avoid the asbestos chuck that may cause the silicon-molybdenum rod to sag and deform due to thermal expansion and contraction, the joint can be coated with a refractory slurry mixed with water glass for firm fixation.

8. When hoisting, the distance between the cone junction of the heating part and the furnace wall is about 25mm-3omm, and the cold end should be 75mm outside the furnace roof. The lower end of the heating part to the bottom of the furnace should not be less than 50mm..

9. The interval between the silicon molybdenum rods in the furnace should not be less than the center distance of the element itself.

10. When hoisting, you must pay attention to the gravity balance of the two cold ends and the wiring part, otherwise it will cause bending and deformation of the heating part.